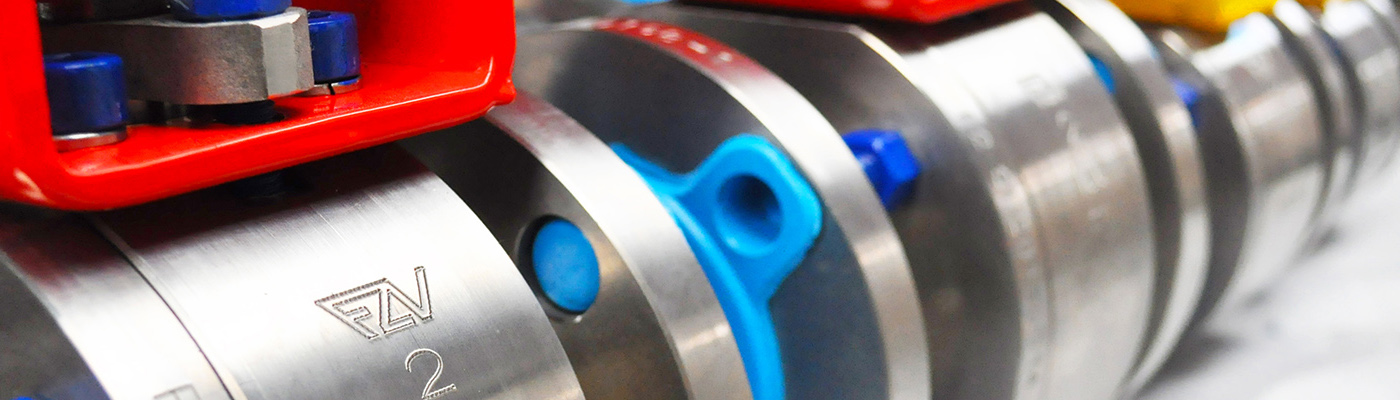

Axial-Flow Type Check Valve

Technical parameters and characteristics:

Product type | ON/OFF |

Product description | Axial-Flow Type Check Valve |

Model | HL43H-Axial-Flow Type Check Valve |

Nominal diameter | 2″~40″ |

Operating temperature | -196℃~593℃(the range of service temperature may vary for different materials) |

Operating pressure | 150-2500 CLASS |

Material | Main material: A216 WCB、WCC; A217 WC6、WC9、C5、C12、C12A、CA15; A351 CF8、CF8M、CF3、CF3M、CF8C、CN3MN、CK3MCUN、CN7M; A352 LCB、LCC; A494 CW-6MC、CU5MCuC、M35-1; A890 4A(CD3MN)、5A(CE3MN)、6A(CD3MWCuN); ASME B 148 C95800、C95500, etc. |

Design standard | API 6D, ASME B16.34 |

Structural length | API 6D, ASME B16.10 |

Connecting end | ASME B16.5、ASME B16.25 |

Test standard | API 6D 、API 598、ISO 5208 |

Operation method | The valve clack is automatically opened and closed under the medium force. |

Application fields | Water, steam, petroleum, natural gas, etc. |

Technical characteristics | The sealing faces of valve seat and valve clack are build-up welded with hard alloy to improve the erosion resistance and extend the service life of valve. |

Streamline flow pass, no bypass of medium, small valve flow resistance, and energy saving | |

Suitable for medium backflow prevention in pipeline or device | |

The floating valve clack structure is adopted to automatically compensate the error caused by wearing during installation and operation, to ensure the tight mating of sealing faces and improve the sealing performance. | |

The opening and closing stroke is short, and it can automatically reset without impact. The valve can be fully opened even under a relatively low flow rate. The closing time is short, which can avoid the occurrence of water hammer phenomenon.

|